On April 1, 2014, Polargy received approval for our patent application for PolarPlex™ Suspended Panel System (SPS) by the US Patent & Trademark Office.

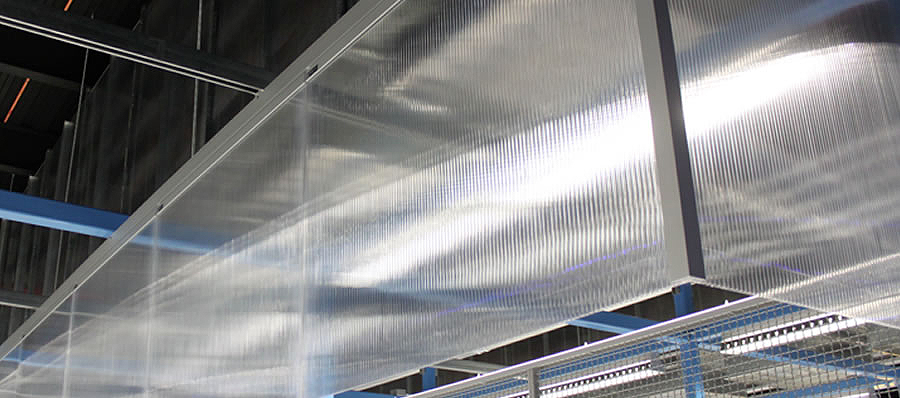

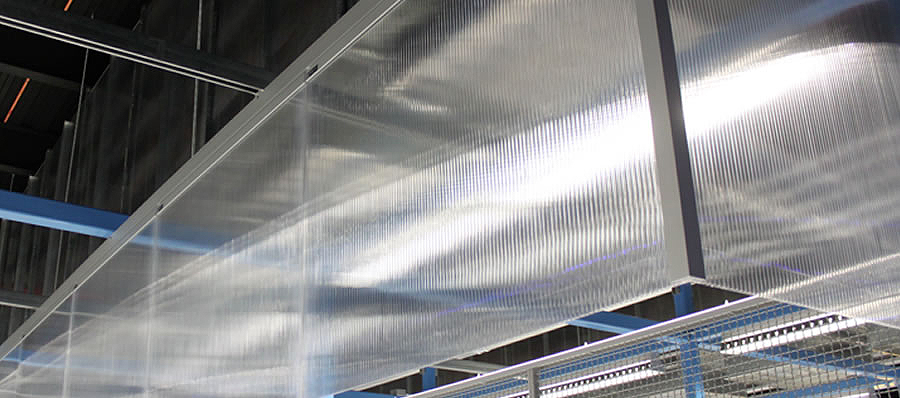

PolarPlex SPS is a ceiling-suspended aisle containment solution for data centers. It’s designed with an innovative quick-connect channel system that holds SPS panels perfectly straight and secure while also allowing quick and easy removal.

Lightweight ceiling-suspended SPS panels offer functional and aesthetic advantages over vinyl curtains yet are competitively priced. PolarPlex SPS provides better thermal sealing, simpler installation, and a cleaner appearance than curtain containment.

For overhead applications, PolarPlex SPS is rack-independent, supported by the ceiling rather than server cabinets. This design enables cabinets to be moved in and out without affecting the containment system. In containment environments built with our Overhead Prefabricated System or Floor Mounted Infrastructure, full-length SPS panels can fill gaps between racks or completely isolate the aisle during commissioning.

CEO of Polargy, Cary Frame, reports: “PolarPlex SPS has filled a product gap in data center containment for at least the past year and we’re delighted to receive patent approval for this invention. The novel SPS channel design means these panels hang straight and strong for optimal airflow management, but can be installed and removed quickly and easily without tools. PolarPlex SPS has raised the bar on hot- and cold-aisle containment solutions.”

Watch Cary’s video about now-patented SPS.

We also recently announced a major update to its website www.polargy.com which now features CAD, BIM, and SketchUp design files for Polargy containment solutions. These freely downloadable design files help data center architects and engineers quickly evaluate and spec our containment solutions for new construction and retrofit projects.

See further details about SPS here.

I had the pleasure of meeting perhaps the industry’s only data center comic writer Diane Alber at the AFCOM Data Center World event last week. Diane is the creator and writer of the Kip and Gary Data Center comic and technology blog.

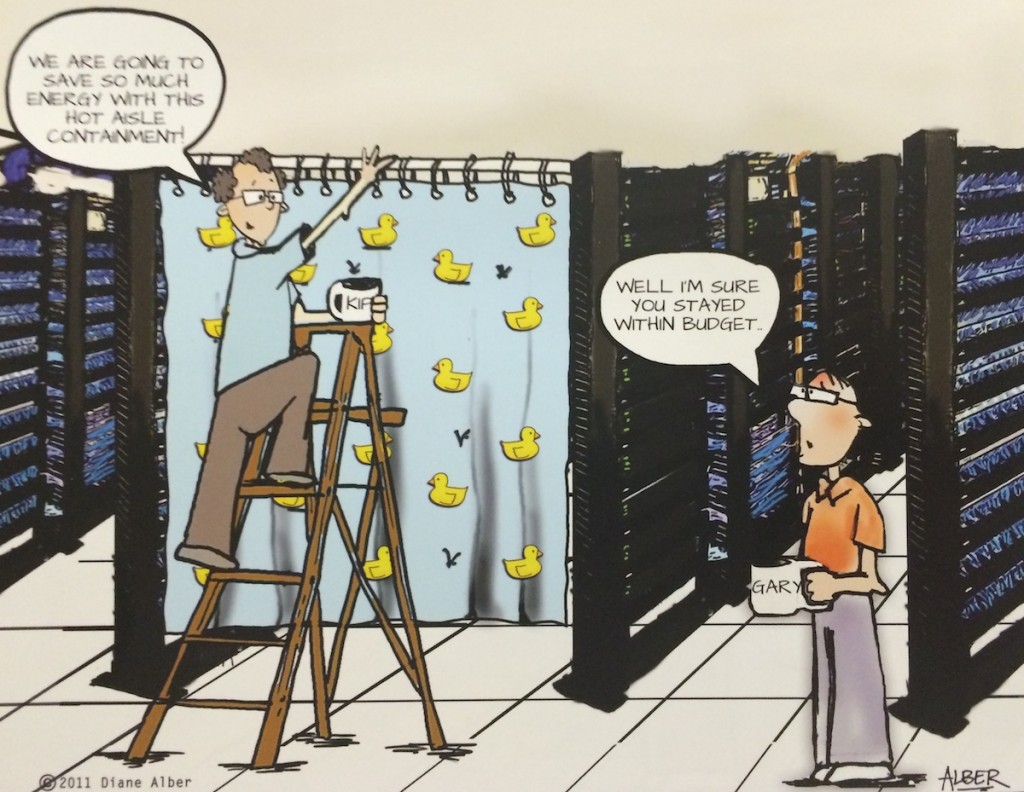

I had the pleasure of meeting perhaps the industry’s only data center comic writer Diane Alber at the AFCOM Data Center World event last week. Diane is the creator and writer of the Kip and Gary Data Center comic and technology blog. I particularly liked this comic from Page 24 poking fun at some people’s understanding (or expectations) of Hot Aisle Containment. Just so you know, rubber duckies cost extra.

I particularly liked this comic from Page 24 poking fun at some people’s understanding (or expectations) of Hot Aisle Containment. Just so you know, rubber duckies cost extra.

delivery into the region:

delivery into the region: Polargy has partnered with Anixter for most of our product deliveries into the LatAm region which allows us to leverage local boots on the ground to handle most of these logistical, tax, and duty issues.

Polargy has partnered with Anixter for most of our product deliveries into the LatAm region which allows us to leverage local boots on the ground to handle most of these logistical, tax, and duty issues.